Advanced Materials for Demanding Applications

DuPont™ Cirlex® is a thick 100% polyimide adhesiveless laminate with the excellent electrical, physical and chemical performance characteristics of DuPont™ Kapton®.

- Available in thicknesses starting at 8mil (.008”, 0.2032 mm

- UL® 94VO rated

- Withstands extreme environments: -269°C (-452°F) to 351°C (664°F)

Cirlex® is used in applications spanning a wide array of industries including semiconductor manufacturing, aerospace and defense, industrial, electronics, medical, and energy.

Cirlex® and Fralock

For over 40 years Fralock has supplied high-quality material solutions for the global marketplace and is DuPont’s sole licensee for the production of Cirlex® worldwide. Fralock provides design, engineering, and manufacturing of specialty components and subassemblies made from Cirlex® for critical applications requiring high reliability.

Cirlex® is one of the many advanced materials used to manufacture components in our diverse product family. Made from 100% DuPont™ Kapton® polyimide film, Cirlex® is a material that delivers performance and value for all your demanding material applications.

Unsurpassed Performance

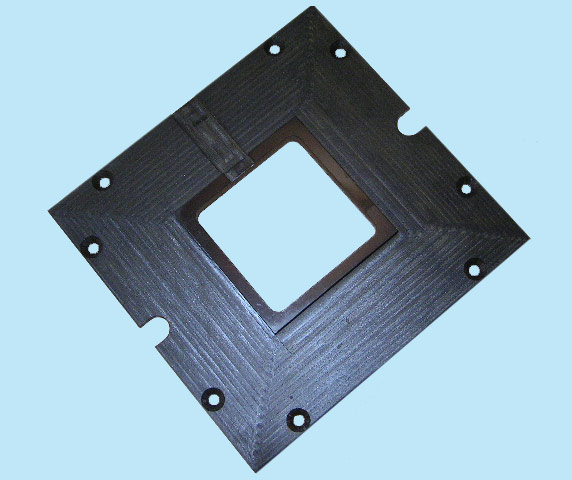

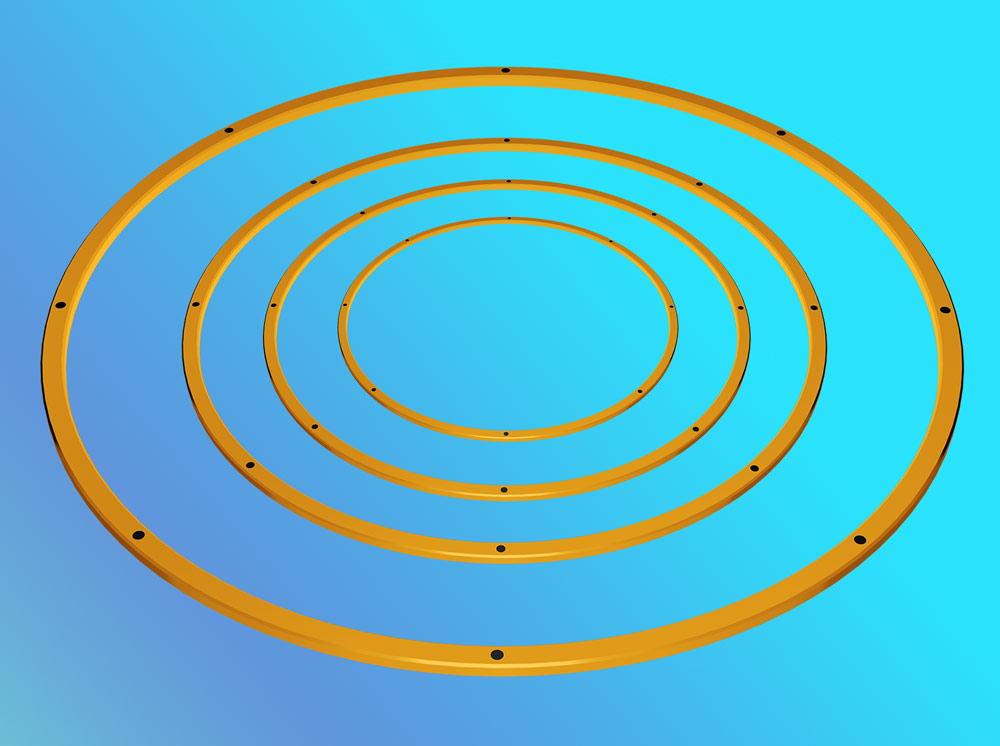

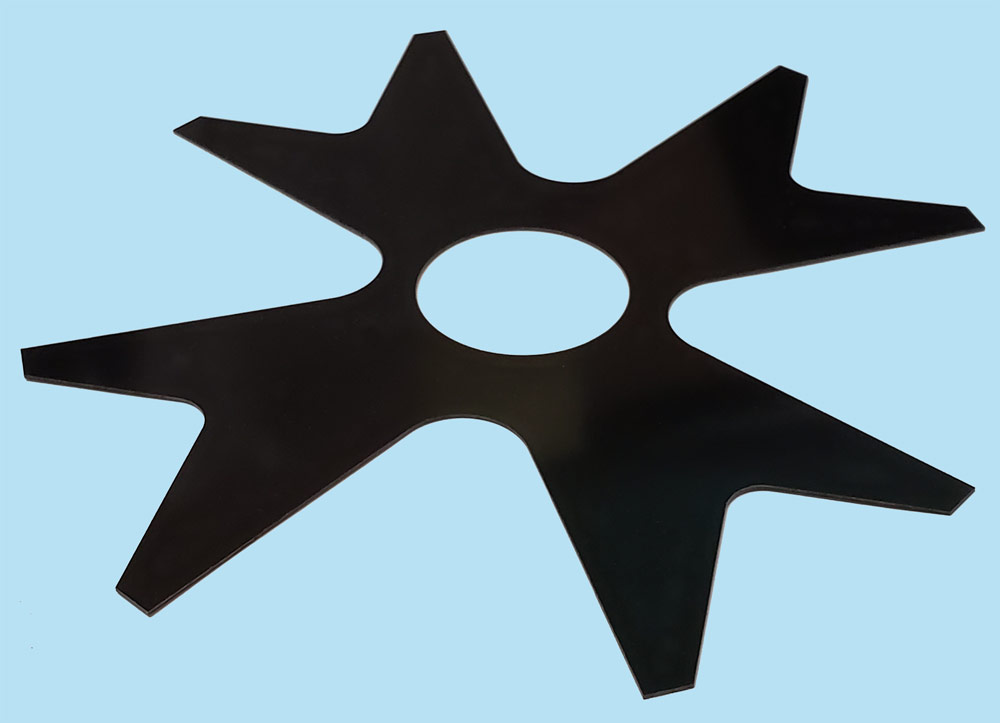

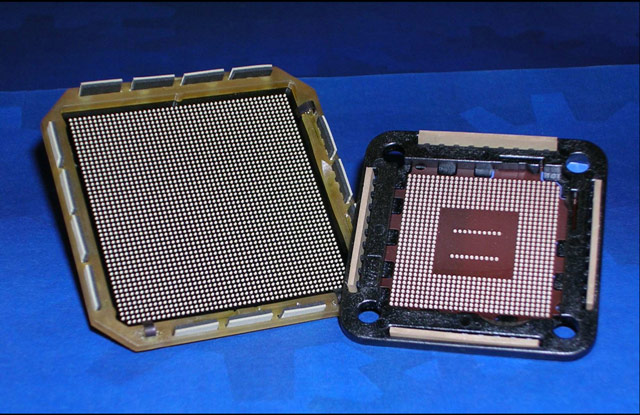

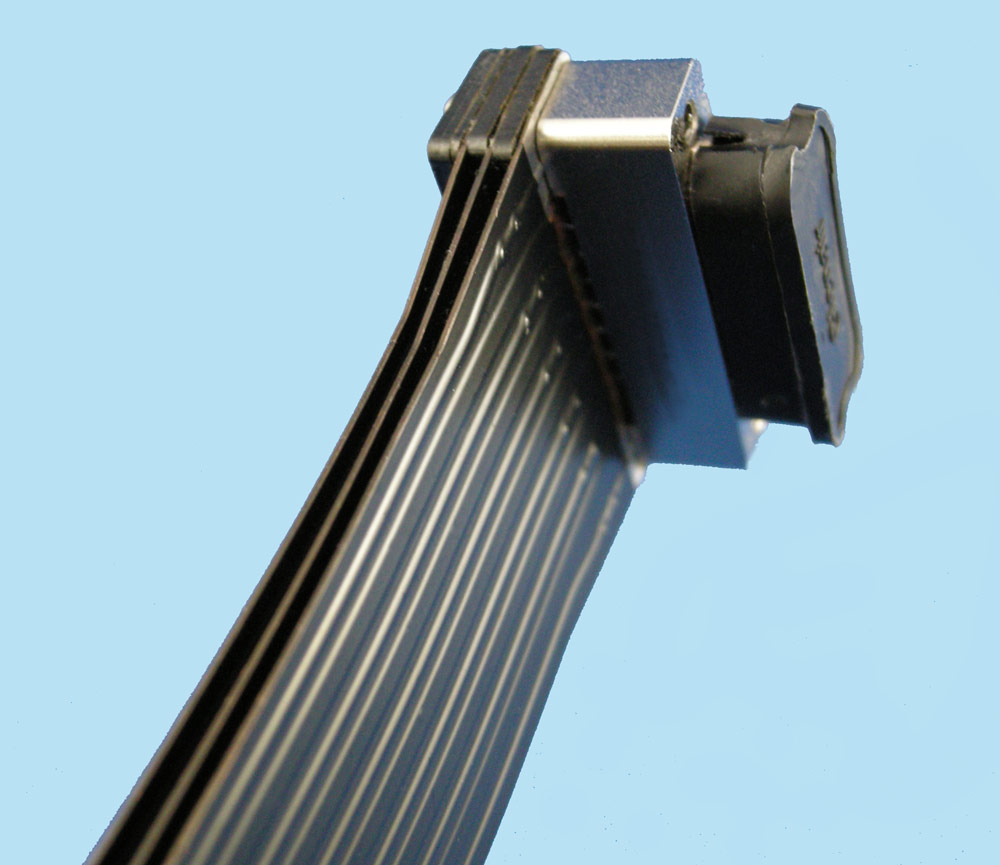

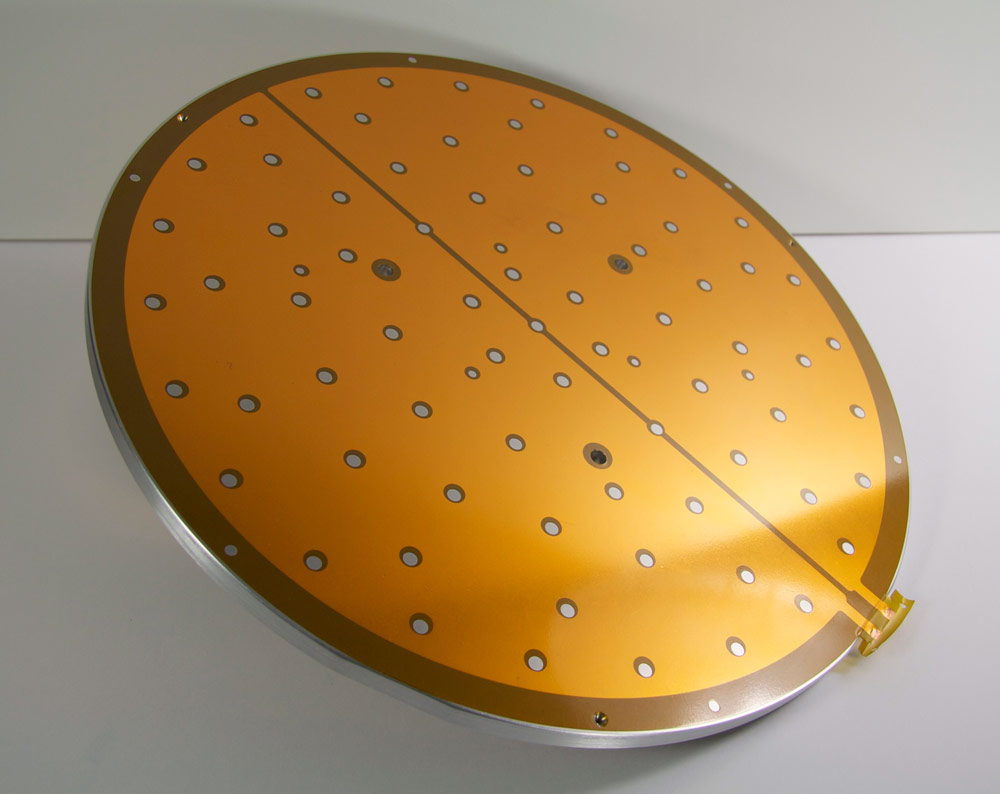

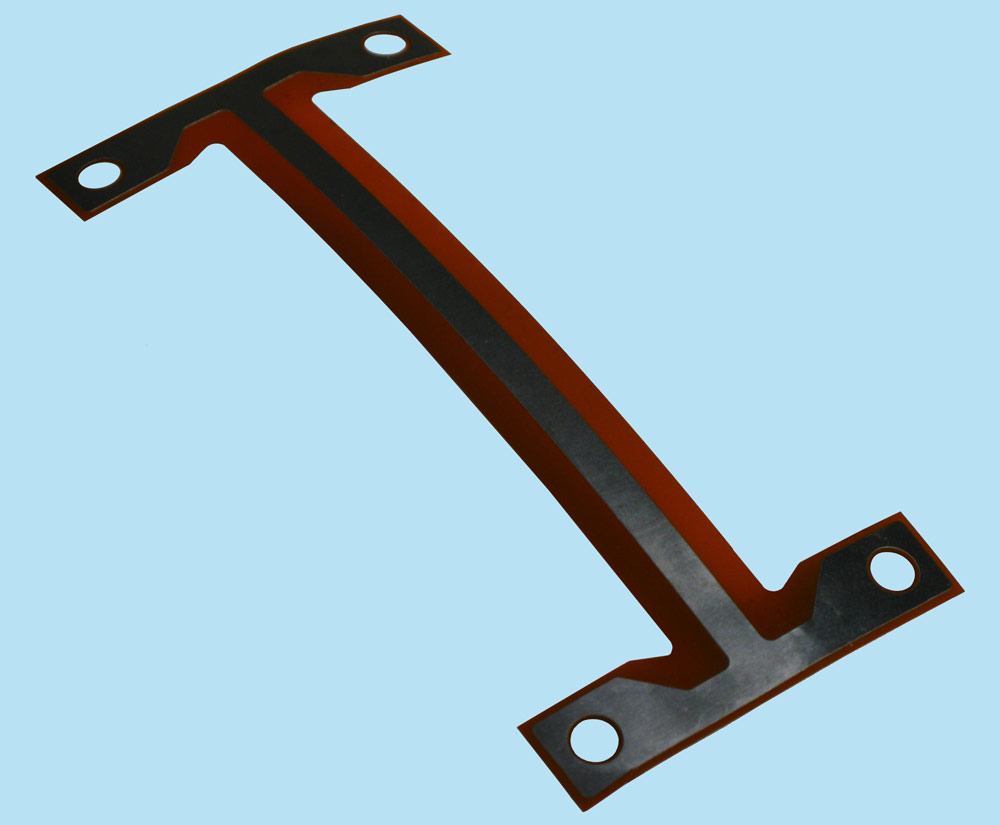

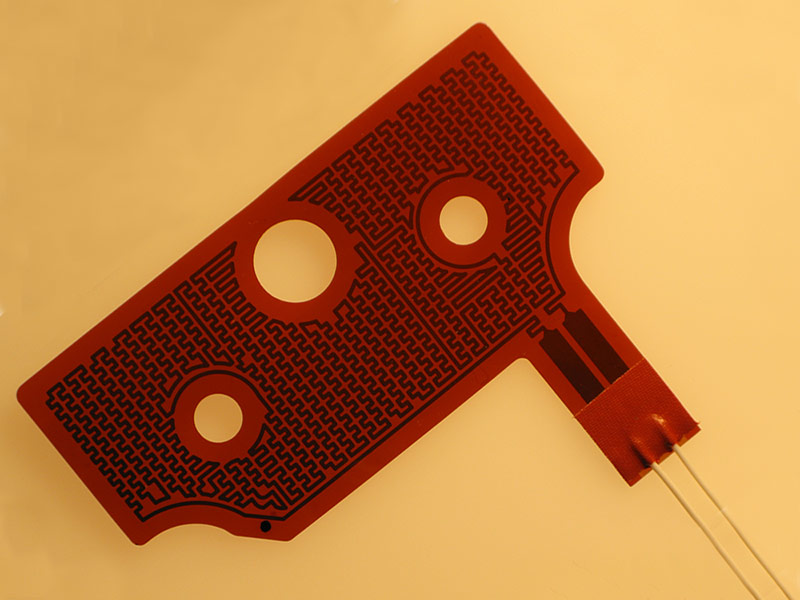

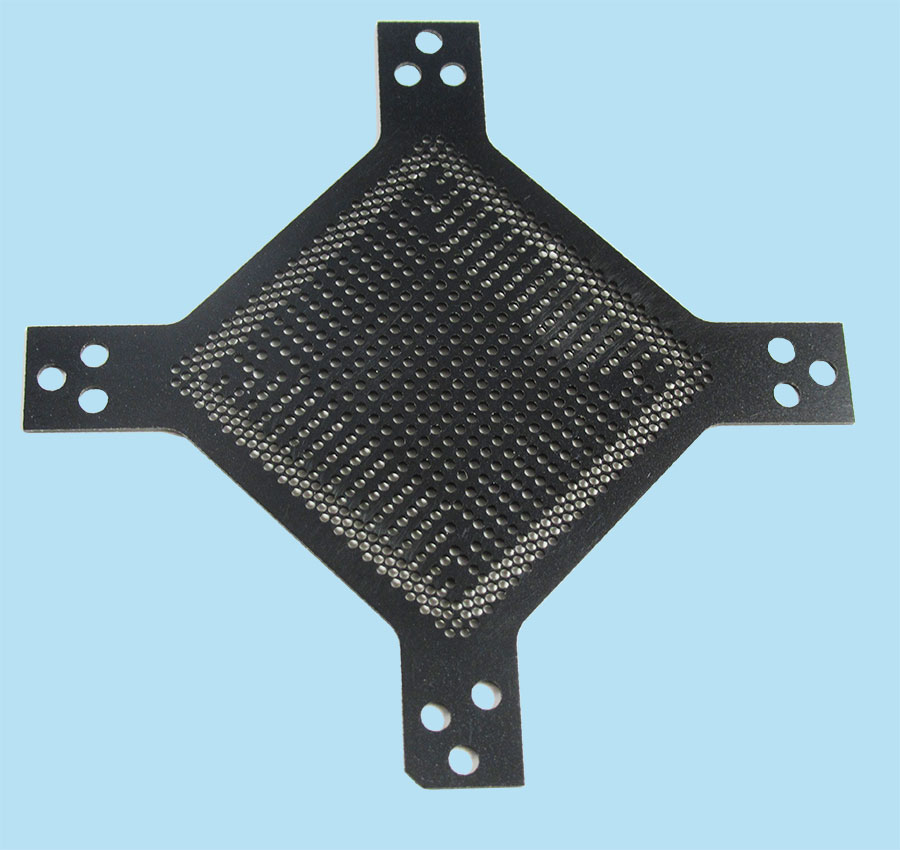

Cirlex® has been developed to fill the growing requirement for thick all-polyimide materials, stemming from a wide variety of industries for applications such as flexible encapsulated heaters, sealing shims, gasket rings, stand-offs, component stiffeners, washers, electrostatic chucks for semiconductor manufacturing, or thermal blocking and electrical insulation in aerospace applications.

If you are looking to replace current applications using ceramics or DuPont™ Vespel®, or upgrade to high-performance polyimide materials, Cirlex® offers material flexibility and an expanded range of thickness options unattainable with cast resins or laminated constructions using adhesives. The excellent chemical, physical, thermal and electrical properties of Kapton® in thick sheet format is unique in today’s material marketplace.

Traditional laminates are notoriously unreliable at temperatures that exceed the Glass Transition (Tg) of the adhesives used in their constructions. You can count on Cirlex®’s integrity at extreme temperatures, from cryogenic at -269°C (-452°F) to as high as 351°C (664°F). In addition, it is readily modified/machined by laser cutting, drilling, machining and chemical etching.

Fralock’s Adhesiveless Laminates

Cirlex® is made with Fralock’s exclusive pioneered adhesiveless bonding technology, eliminating the adhesive interface where many problems occur. Polyimide is closely matched to the CTE of copper and can also be used to bond many other metals with bond strengths typically > 10 pli.

If your application requires high temperature resistance, dimensional stability, low outgassing, durability, and solvent resistance, Cirlex® adhesiveless laminate is your ideal material.

For more information about Cirlex® and Cirlex® components, contact Fralock